Hit Between The Marks

11/18/2015

When inserted correctly, PVC pipe's gasketed joints have proven to be the superior performer due to joint integrity, flexibility and forgiveness in service. The reason is because PVC offers the best pipe joint available in the water and sewer industry. Despite what you may have heard, the PVC gaskedted pipe joint is watertight. For it to successfully pass your acceptance test it must be leak free.

PVC makes it effortless for the installer to assemble pipe in a simple four-step process. Clean the joint, lube, align and slide the spigot so the first mark is not visible outside the bell and the second line remains visible. This assures the pipe would be neither over nor under assembled.

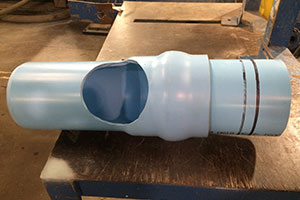

Photo #1 two insertion lines prior to the pipe being assembled. The goal is to assemble the pipe so only one insertion line shows.

Photo #2 shows a properly assembled joint section. Take notice that the installer “Hit Between the Marks." The insertion line is showing just at the lip of the bell. The photo shows a great look at the gap for the properly inserted spigot. This gap is critical to allow for expansion and contraction as well as flexibility during the life of the system.

If the second insertion mark is not visible after assembly, the pipe was over-inserted or homed. The installers would have to pull back and then reinsert the pipe to correct length. On the other hand, if the first mark is short of the lip of the bell, the installer would have to push a little further until the insertion line is showing just at the lip of the bell.

Though PVC is easier to install and more forgiving than other products, it should still be properly installed with as much care as any other product. This will help ensure maximum system life.

Photo #3 shows pipe that have been over-inserted. This causes the joint to have no flexibility; therefore they cannot expand and, in fact, can be under significant stress.

PVC pipe manufacturers such as Diamond Plastics feel so strongly on proper installation, that they will consider the warranty void if the installer chooses to ignore these simple guidelines.

The other significant factor about over insertion is the cost. If every installed joint is over-inserted by 2 inches on a 20,000 foot project (with 20' joints) that is a loss of 2000 inches of laying length (166.7 feet) of pipe which will have to be ordered to complete the project. On four (4) inch or six-inch (6) pipe this won't be a lot of money. But for forty-eight (48") inch pipe this could cost an additional $30,000.00 depending upon the pressure class of the pipe. This is significant. Maximum laying length is achieved by proper insertion to the first line from the end of the spigot. Several methods may be employed to prevent over insertion. For a discussion of these methods contact your Diamond Sales representative www.dpcpipe.com

Obviously, the choice is clear. Hit between the marks and everybody wins; the installer, the utility and the manufacturer.

Diamond Plastics Corporation manufactures gasketed PVC pipe in diameters from 1½ in. through 60 in. for water distribution, transmission, irrigation, drainage and sewage applications including AWWA C900 and C905 products from 4 to 60 in. With seven plants across the United States and more than 30 years of experience in production, Diamond is the World's leading manufacturer of quality PVC pipe products.